customised electric motors

A new generation electric motors

Whether automotive, aviation, off-highway applications, industry and robotics or even racing: electric motors are the drives of the future.

Additive Drives develops electric motors that are perfectly tailored to the customer’s wishes and specific needs. In addition to power densities of 25kW/kg, efficiencies of up to 98% can also be realised in this way.

Electric motors For extremes

The development of electric motors for aviation and motorsport requires extreme power densities and maximum performance. Automotive and industry demand maximum efficiency and the most effective cooling. Off-highway applications demand the highest torques in the smallest installation space.

Customized Development

Depending on the application, different technologies and conductor structures can therefore be used: Radial flux or axial flux motors, single coils, classic hairpin windings with optimised winding heads or the patented Additive Drives Next Pin!

The innovative manufacturing processes enable the production of drives in all quantities, from single units to large series, and unprecedented design freedom. We support our customers individually from the initial idea through to realisation.

The future of electric motors

With up to 45% more power, Additive Drives takes electric drives to the next level. 2D and 3D electromagnetic simulation paired with production-orientated CAD design and patented manufacturing methods enable the most innovative designs for electric motors.

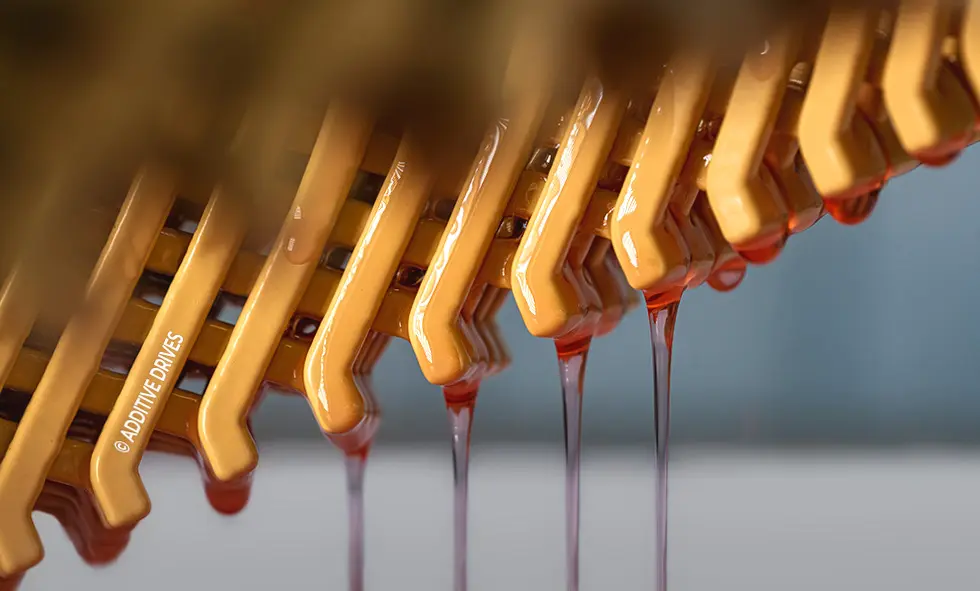

Optimized cooling for the highest demands

There are many ways to cool electric motors, from air cooling and water cooling to direct oil cooling. However, the most effective way of cooling is still to reduce losses!

While air cooling can be used in stationary industrial applications, power densities above 25 kW/kg can only be realised using modern cooling concepts such as integrated oil cooling. Various concepts are possible:

– Direct cooling of the slots

– Oil cooling of the stator core near the slot

– Spray cooling of the winding heads

In order to optimise the cooling system, Additive Drives offers its customers thermal simulations during engine development. Endurance and insulation tests are also available to customers.

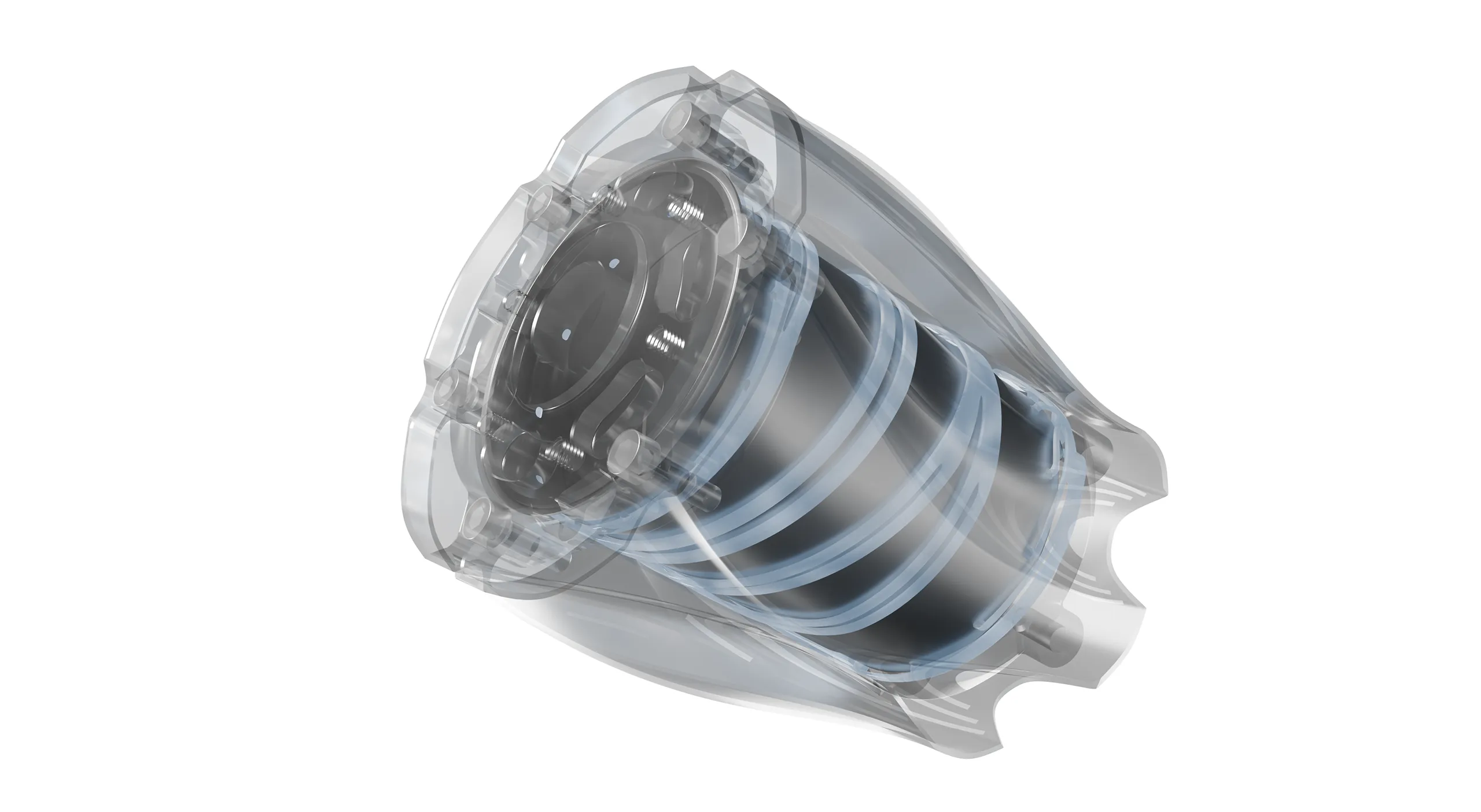

Phase Change Cooling

The world’s most efficient cooling system: Phase Change Cooling takes electric motors to their physical limits. The cooling system utilises the high enthalpy of vaporisation of the special cooling medium to achieve a heat dissipation of 60 kW/l. The physical properties of the coolant allow direct cooling of the stator windings, giving the best possible heat transfer coefficient.

If heat is introduced during the phase transition, the temperature of the cooling medium does not rise any further, so that the motor operates constantly at a maximum of 120°C. The continuous output of the motor corresponds to the maximum output and there is no derating.

Aerospace applications

There are a large number of special applications for electric drives. In the aerospace industry, for example, electric motors can be used as auxiliary drives for pumps or coolant compressors, with state-of-the-art liquid cooling systems and additively manufactured components enabling power densities of over 100 kW/liter.

Modern insulation systems and adapted circuitry reduce partial discharges in electric motors, even in a vacuum and under hostile operating conditions.

Applications

Electric motors move the world. Our motors are used in a wide variety of products and are customised for every application.

Benchmarks

Electric motors at the physical limit! In addition to industrial motors with efficiencies of up to 98%, Additive Drives also develops high-performance motors with power densities of up to 25kW/kg.