Innovative electric motors for innovative products

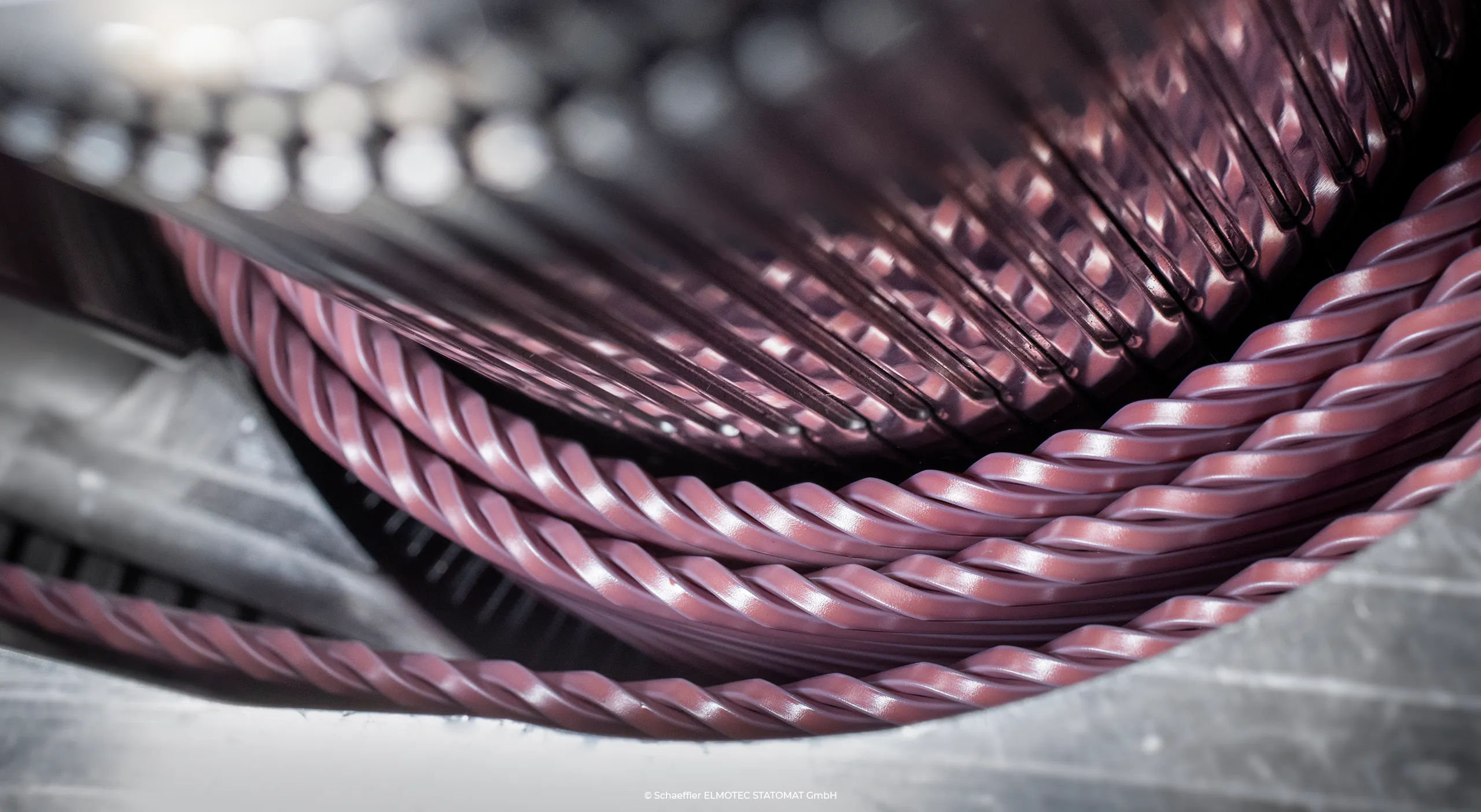

Electric motors are the technology of the future and are being used in more and more industries. The high demands on efficiency and installation space also require creative solutions from developers. Together withDaikin Chemical Europe, we have developed a motor that not only uses the latest insulation methods, but also has integrated oil cooling.

For the first time, such a thin insulation layer can operate PDIV-free even at high voltages The result is not only a motor with a high copper content, but also a motor suitable for use in the aerospace industry. The demanding operating conditions place particularly high demands on the insulation. Test results show not only improved insulation properties of the conductors in the stator, but also a significantly improved overall efficiency of the machine against comparable motors.

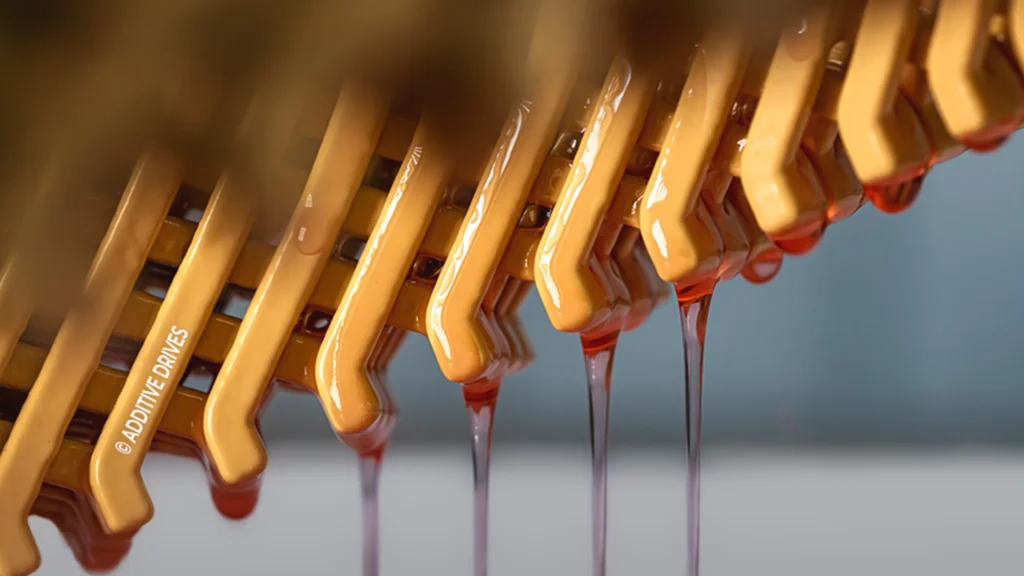

Optimised cooling

The integrated oil cooling in the motors enables efficient heat dissipation at the point where it is generated. Supported by thermal simulation, we are thus able to accommodate particularly high power in a small space.

Innovative conductor structures and optimised cooling enable not only maximum power densities of 25kW/kg – essentially a 100kW motor in the space of a coffee cup – but also unrivalled levels of efficiency. The design of the electric motors is tailored to each application, so that the most suitable motor is used.

By switching to high-efficiency electric motors, many users are taking an important step towards greater sustainability. Additive Drives supports its partners in the development and production of next-generation electric motors.