Electric motors for industrial applications

Highly efficient of electric motors for the planet

Electric motors in industry often work continuously. Improving efficiency is an important lever for saving energy, particularly in pump and fan applications. With efficiencies beyond the norm, Additive Drives offers the right motors for this.

The development of new technologies and the challenge of saving energy are currently driving industry worldwide. Additive Drives is transferring innovative ideas from aviation and motorsport to series production in order to herald the future of electric motors!

Development across Industries

The best way to cool: Avoid losses

There are many ways to cool electric motors, from air cooling and water cooling to direct oil cooling. However, the most effective way of cooling is still to reduce losses!

Depending on the application and frequency range, different conductor structures and technologies can be used: classic hairpin windings with optimised winding heads or the patented Additive Drives Next Pin!

The conductor design is always customised to the customer and each conductor geometry is as unique as its application!

Hairpin Beyond Automotive

Hairpins are the trend technology in the field of electric motors. rectangular copper rods replace the coiled copper wires. Higher copper fill factors and larger cross-sections reduce heat generation and increase the efficiency of the application.

The development of motor technology through additive drives has a significant impact on the overall efficiency of the application. The use of the technology is not limited to the automotive sector, but is also used in aviation, motor sport and industry.

Cost Saving for the planet

Saving energy through more efficient machines not only conserves resources and saves CO2, but also reduces the cost of industrial electricity. The development of energy- and cost-efficient asynchronous machines with efficiencies of over 96% heralds a new era in industrial motors. – A more sustainable world of tomorrow

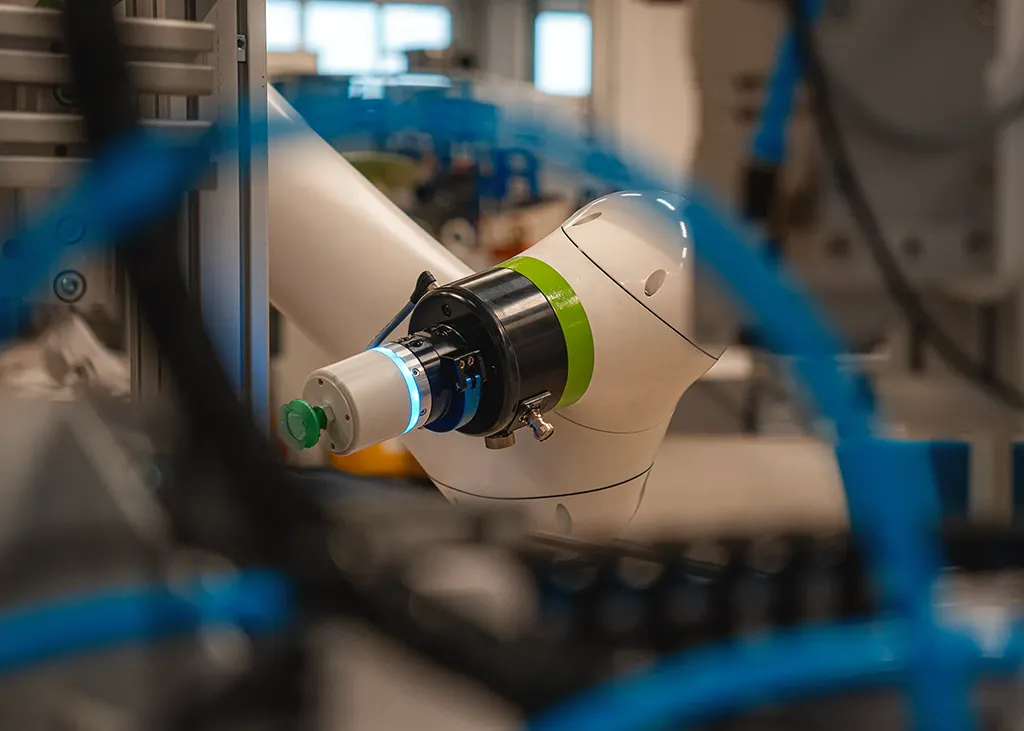

High Torque Motors for Robotics

High-torque motors are extremely compact, deliver high torques and are maintenance-free. Torque motors are always the first choice for applications that are highly dynamic, backlash-free and work with high torques.

Highly efficient and compact torque motors are easier to handle than complex hydraulic solutions and operate at higher efficiency levels. Whether industrial or humanoid robotics: the future belongs to torque motors.

Developement for the planet

Today’s electric motors often utilise technologies from the last century.

With increasing demands for energy efficiency and CO2 savings, the need for new solutions to make the future of drive technology more sustainable is also growing.

Additive Drives was founded out of a deep desire for more innovation and has developed into a pioneer of electric drives. For years, we have been dedicated to developing new technologies in order to realise a new generation of electric motors. With solutions such as the Next-Pin, we have the future of electromobility on offer.

Technology

Customised electric motors: Depending on the application, different conductor structures and technologies can be used: Single coils, classic hairpin windings with optimised winding heads or the patented Additive Drives Next Pin!