Electric motors for heavy-duty applications

Highest performance in the smallest installation space

Electric drives are becoming increasingly important in the off-highway sector, whether as a replacement for hydraulic drives, e-boost or electric power splitting: Maximum power densities and unrivalled efficiency levels are redefining the future of drive systems.

Development across the boundaries of technology

The development of new technologies and the challenge of saving energy are currently driving industry worldwide. Additive Drives is transferring innovative ideas from aviation and motorsport to series production in order to herald the future of electric motors!

Traction drives for the highest demands

Traction drives in mobile machinery have to withstand extreme loads, and hybrid concepts or electric power splitting can make an important contribution to major leaps in efficiency here. With modern concepts such as integrated oil cooling and maximum torque densities, even extreme performance requirements can be met.

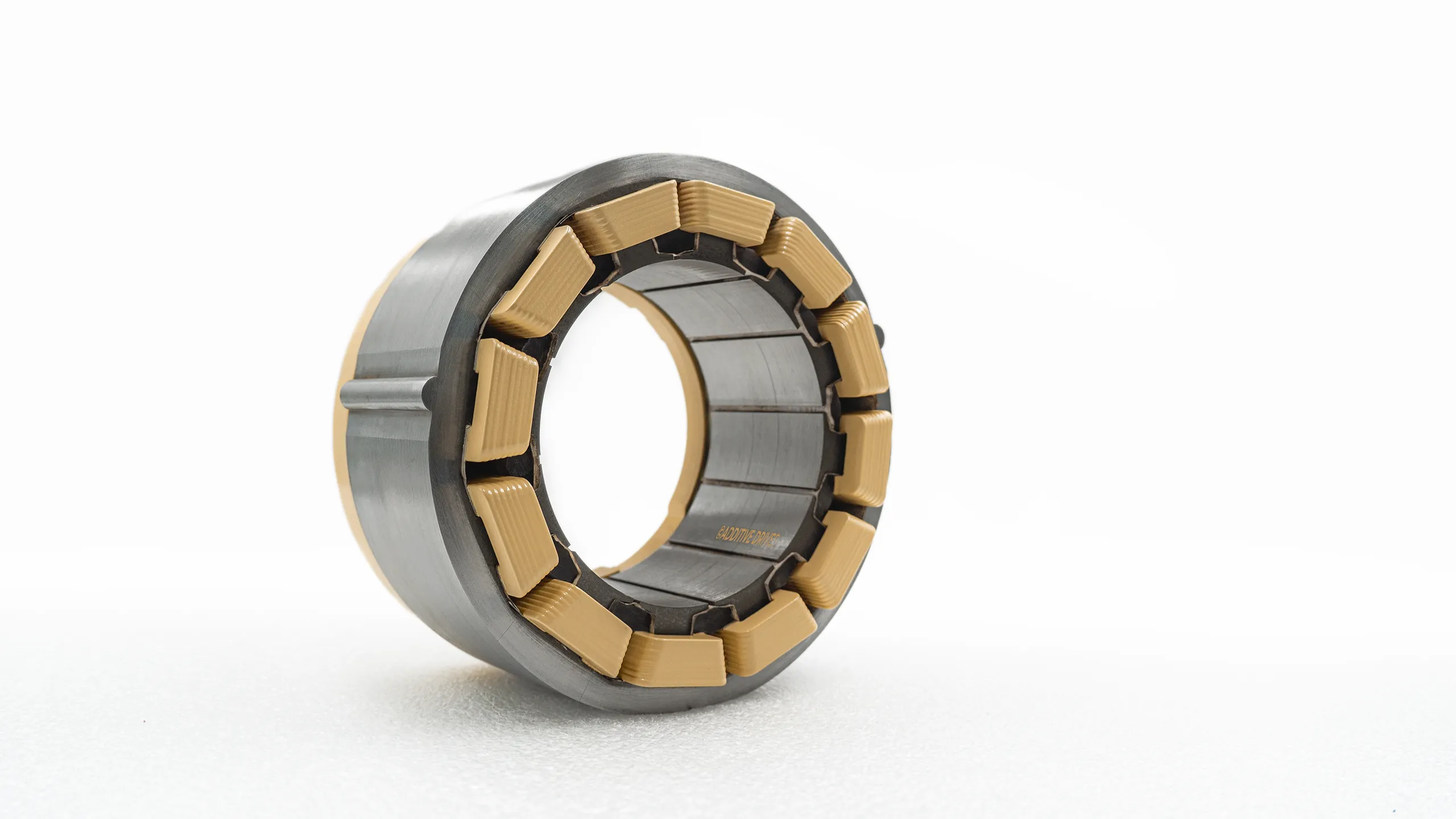

Torque Motors

High-torque motors are extremely compact, deliver high torques and are maintenance-free. Torque motors are always the first choice for applications that are highly dynamic, backlash-free and work with high torques.

The perfect geometric adaptation of 3D-printed individual coils not only enables higher efficiencies than with the classic round wire winding, but also significantly increases the torque density!

Simpler, better, more sustainable!

Today, high-torque motors are replacing hydraulics and complex gearboxes in many applications. simplified the control and architecture of the drivetrain. Electric auxiliary drives for implements can also be controlled more precisely and independently of oil temperature and pressure with electric solutions.

The future of auxiliary drives is electric!

Energy recovery for greater efficiency

The use of electric motors allows the simple recuperation of energy; if a kinematic system lifts a heavy load downwards, the potential energy can be converted back into electrical energy. Adapted motor designs can reduce the energy requirement by up to 20% and extend the running time in mobile applications!

Development for the planet

Today’s electric motors often utilise technologies from the last century.

With increasing demands for energy efficiency and CO2 savings, the need for new solutions to make the future of drive technology more sustainable is also growing.

Additive Drives was founded out of a deep desire for more innovation and has developed into a pioneer of electric drives. For years, we have been dedicated to developing new technologies in order to realise a new generation of electric motors. With solutions such as the Next-Pin, we have the future of electromobility on offer.

Technology

Customised electric motors: Depending on the application, different conductor structures and technologies can be used: Single coils, classic hairpin windings with optimised winding heads or the patented Additive Drives Next Pin!