Interview with EV Tech Insider

We recently had the opportunity to give the specialist magazine EV Tech Insider an in-depth interview about us and our products. Read the complete article here:

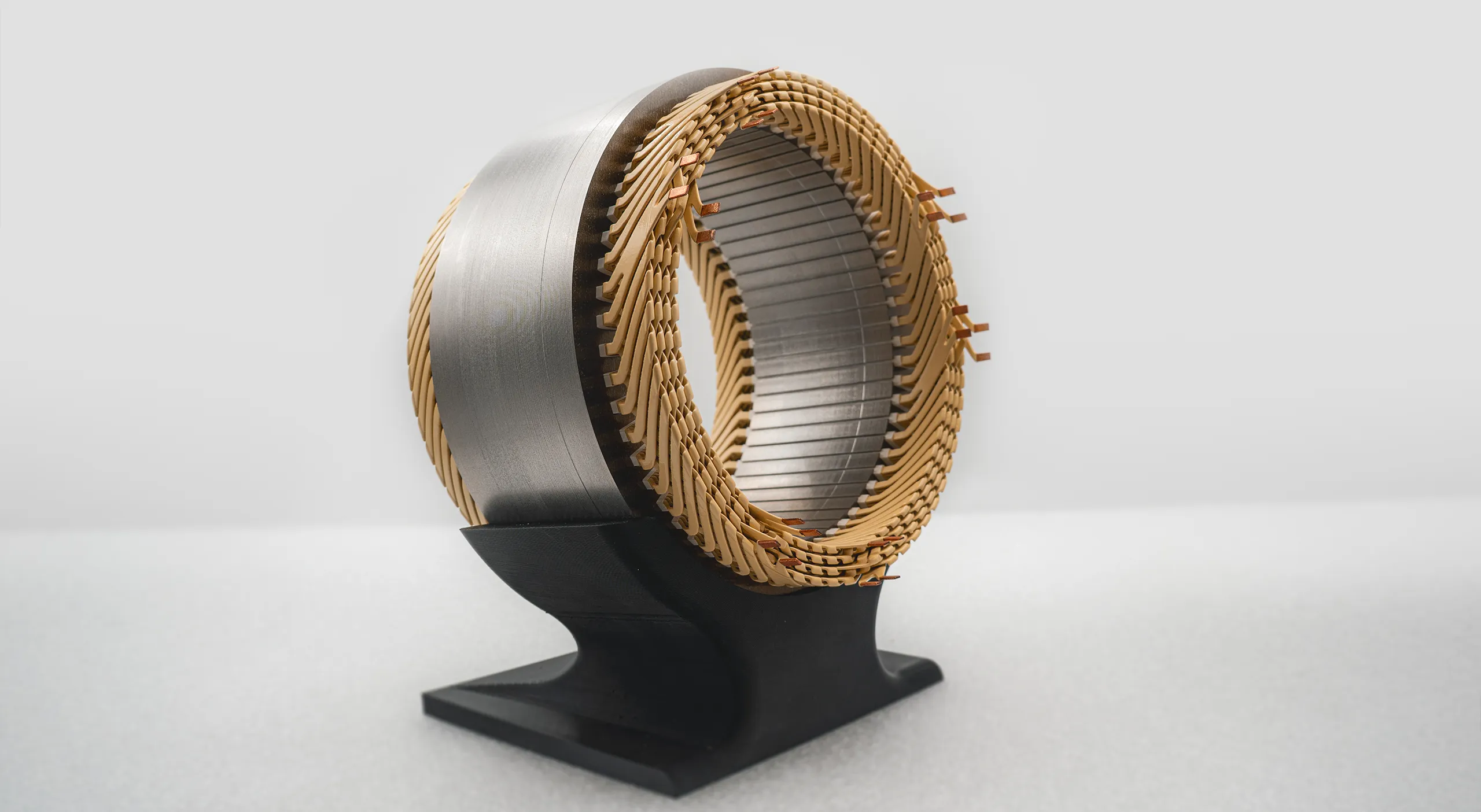

What are the advantages of using 3D-printed motors compared to conventional manufacturing?

One: Design freedom. A better design simply means a better engine. With 3D printing, you can test and improve important properties such as thermal performance, winding topologies, insulation material, etc. Ultimately, we achieve up to 45 % higher power densities compared to conventional production.

Two: Rapid time to market and lower prices per unit. Whether axial or radial flux, our 3D printed motors have the shortest time to market in the entire industry. As no complex tooling is required to manufacture the motors, the costs per unit are reduced. With 3D printing, we can offer our customers customised electric motors in any quantity. The development of electric motors has never been easier, especially for customers with high requirements but small quantities.

3D printing produces engines that can be manufactured more easily, better, cheaper and faster.

We’re split into two units:

One unit is dedicated to prototyping. We have by far the shortest time to market in the entire EV industry when it comes to the production of motors, whether they are axial or radial flux motors, which means we are faster and cheaper than conventional manufacturing.

The other unit works in series production, and here everything revolves around customized electric motors. We develop the specific electric motor that is perfectly tailored to your needs. For example, high-performance electric motors with power densities of over 25 kW/kg for customers in the aviation industry or large air-cooled asynchronous machines with efficiencies of over 96%.

Our main value proposition: customized electric motors in quantities from 1 to 100,000, which is what we are currently aiming for. Our main product is customized traction motors for electric vehicles, but we also offer motors for other types of mobility, from e-bikes to multi-megawatt applications in aviation, and also industrial applications such as robotics or general pump or fan applications.

Our applications are widespread, we stay technology agnostic about all kinds of motor technologies.

How does 3D printing allow for better thermal performance?

The best way to cool is to combat AC losses. This is a big challenge, but we can improve it in various ways.

Cable insulation is one of the biggest challenges for EV motors in terms of cooling, service life, partial discharge in aviation, etc. Because it is such an important piece of the puzzle, we are constantly developing and testing new insulation materials that enable higher copper fill factors. We have a strategic partnership with material manufacturer Daikin Chemical to develop primary insulation and have a number of ideas on the horizon that will enable thinner insulation, better oil compatibility and longer life, improving motor efficiency.

We’re also designing new wire technologies, including our patended NextPin technology, which significantly reduces AC losses. The idea behind it is an innovative conductor technology that combines the advantages of two worlds: the copper fill factor and the processing of solid conductors or hairpins with the high-frequency properties of stranded wires. By using NextPin technology in the automotive sector, for example, energy savings of up to 50% can be achieved over long distances.

When we optimize electric motors, we take a very close look at the conductor structure. Through the targeted use of 3D printing, we can not only achieve more efficient designs, as we are not restricted by bending radii or tools, but we can also incorporate special features into the conductors, such as cooling integrated into the conductor. Depending on customer requirements, we can also produce conductors made of aluminum, for example, whereby the entire development process is open to all technologies.

NVH is always a big topic for developers. Do you have any features about your engines in terms of NVH? Has this improved at all with your technology?

In order to get a grip on NVH, it is important to optimize the stator circuitry and generate a sinusoidal air gap field. The effort behind such a circuit is often associated with high costs in conventional production. This can easily be avoided with our innovative processes. Reducing NVH problems not only lowers the noise level, but also increases the service life and efficiency, which is why we are always addressing this issue.

What sort of material formulations are you using, and do you see any new formulations coming soon?

We only use 3D printing when it makes technological sense. There have already been attempts to print complete motors in the past, all of which failed due to the high costs and, in some cases, poorer efficiency than a conventional electric motor.

We differentiate between the sheet metal packages, the conductor structures and the housing. For example, it can make sense to print a housing because a special geometry helps to optimize cooling. Aluminum alloys are usually used here. The material development of copper and aluminum is now so advanced that the printed materials can have better material properties than, for example, a drawn copper wire, as cold forming no longer takes place.

We monitor the market very closely so that we can always offer our customers the best possible solution.

What type of customers are you gaining traction with?

We work with several major manufacturers, many OEMs, Tier 1 companies in Germany and many more from the USA. We also have a growing customer base in non-automotive applications such as aviation. Formula 1 is also interesting for us, especially in view of the new regulations in 2026.

There are countless applications that require more efficient, customisable motors with maximum performance.

The development and production of engines is currently very time-consuming. Our experienced team has first-hand experience of how painful it is to put engines through months or years of iterations on the test bench and into vehicles – it’s too long.

That’s why we founded Additive Drives, to help manufacturers shorten their time to market with better technology.

What are the electric aviation projects you’re working on?

The eVTOL market is still growing and developing, but our results show enormous potential. Compared to the automotive industry, there are a number of unique challenges and requirements, e.g. in terms of functional safety and outage operation.

What happens if your car’s engine fails? You pull over to the side of the road and that’s it. With an eVTOL, that becomes a pretty dangerous situation. Our designs include functional safety concepts, such as redundant winding systems in combination with our new insulation materials.

eVTOLs also require very high power density, and we just launched a new application exceeding 25 kilowatts per kilogram of continuous power. It’s all about keeping the eVTOL safe and making a fair trade between power and weight in these instances.

Electrification is also used in many other areas, such as construction, agriculture and mobile machinery. In these applications, our motors can be much more efficient than current hydraulic solutions. Electric drives enable the simple control of various systems or, for example, recuperation during cyclical work, such as with excavators. Boost solutions, such as those used in Formula 1, or hybrids are also possible. There are already attempts to transfer the electrical power of tractors to attachments, for example, in order to develop more efficient overall systems. The requirements in terms of installation space and power density are almost the same as in aviation, and here too we are pushing the boundaries of what is feasible.

Have you found a lot of success in the high-performance market?

Although we see high-volume production as one of our key propositions, we are working with a few high-performance customers, especially for our motors with over 25 kilowatts per kilogram.

We achieve this by focusing on optimizing the rotor and stator unit as the main loss components as well as the windings. Better cooling, better winding topologies, new insulation material and ultimately many design freedoms that we have through our manufacturing process enabled by 3D printing. By combining these factors, we achieve up to 45% higher power density compared to conventional manufacturing.

There is no single key technology, but a combination of different technologies that lead to higher power densities and efficiencies. We combine years of experience in the development of electric motors with unique expertise in innovative manufacturing.

Anything else that stands out about 3D printing that’s a huge advantage?

Of course, you have no tooling costs. For small series production, we can enable super-complex windings without any kind of tooling. We’re talking 12 conductors per slot, 16 conductors per slot in hairpin designs, which would be extremely difficult to produce conventionally.

What are some of the questions engineers typically ask your team?

Ultimately, it depends on what our best friend, the test bench, tells us. Regardless of whether we manufacture conventionally or with 3D printing.

As a rule, engineers mainly ask whether our material has the same properties as conventionally manufactured motors. Developers also ask about the insulation properties. We exceed expectations in both of these areas.

Everyone knows that 3D printing is an expensive process. We use 3D printing as a targeted tool precisely when it is necessary and useful to meet the requirements of an application. The same applies to the use of high-performance materials and technology approaches: not every technology from aviation or motorsport can be integrated into a road vehicle or an industrial engine.

We always pursue the goal of realizing the customer’s requirements in an economically sensible way. This creates considerable benefits for customers in series production approaches. Our current focus, as I mentioned, is between 1 to 100,000 units, but our upcoming manufacturing methods will bring this number even higher.

What’s the vision for Additive Drives?

Our mission is to simplify electrification. Several new manufacturers are designing from scratch, for example in the commercial vehicle and aerospace industries. Many of these companies are designing their first powertrain systems, and we are working side by side with them to develop their engines with the highest possible performance and efficiency.

Around one-third of the world’s energy is currently used in electric motors, and we want to develop an entirely new generation of sustainable high-performance motors to impact the planet.

We want to become not only the world market leader for pre-printed electric motors but all customized electric motors, which is not on the table for many manufacturers now because they’re all focused on big series manufacturing. In the short term, we are working on quantities of 1-100,000 units for industries such as the off-highway sector, which usually comprises around 3,000 units per year.