Customer Stories

Customised Electric Motors – We provide insights into some of the 300-plus customer projects we have completed! Together we are setting new standards!

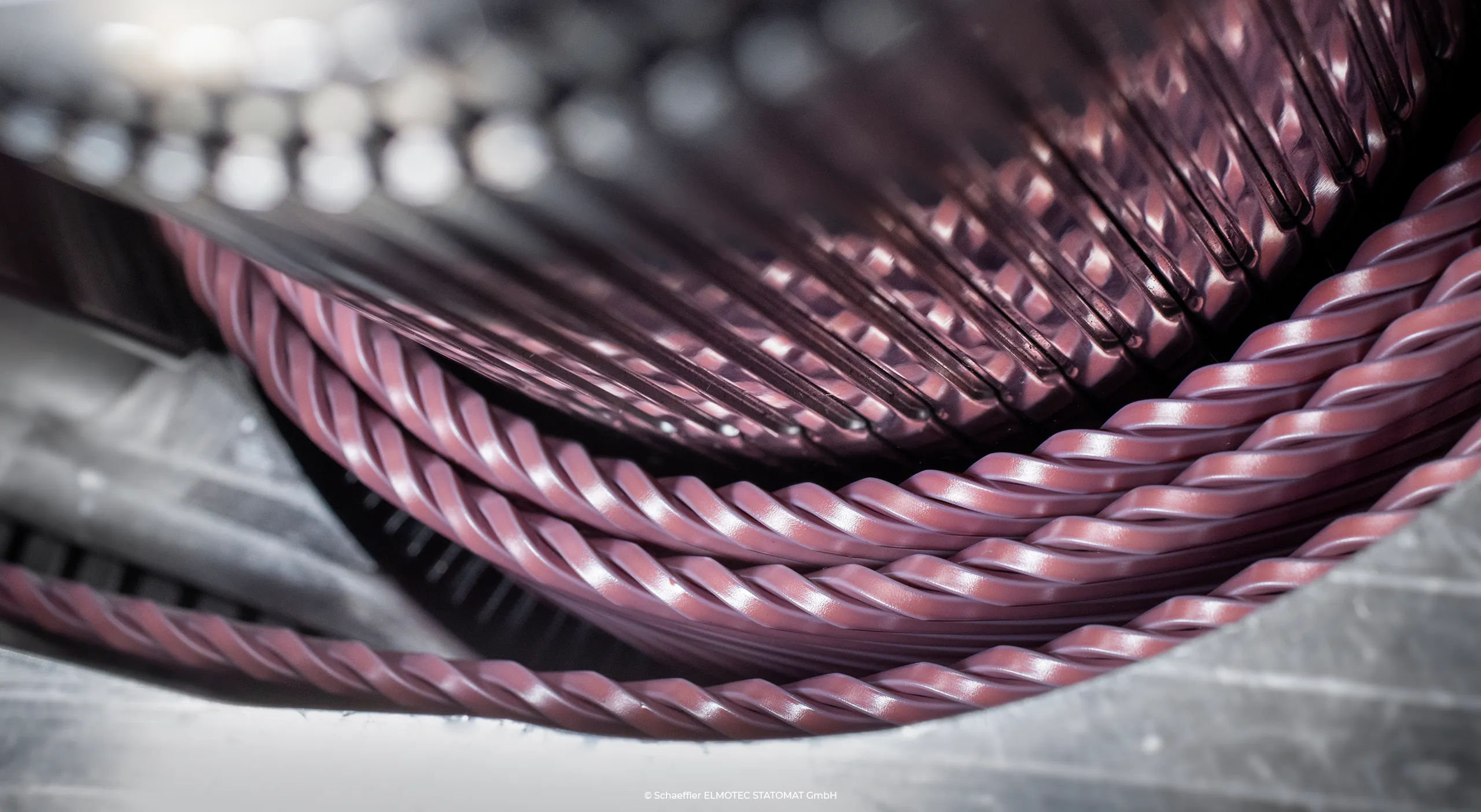

As part of a collaborative research project with the Ford Motor Company, we have optimised a hairpin stator to achieve higher efficiency and better packaging than ever before. By combining hairpins with a constant cross-section and variable profile with our optimised production technologies, we have improved the performance of the electric motor!