Elektromobilität vereinfachen: Vom Prototyping bis zur Serienproduktion für Hochleistungsanwendungen.

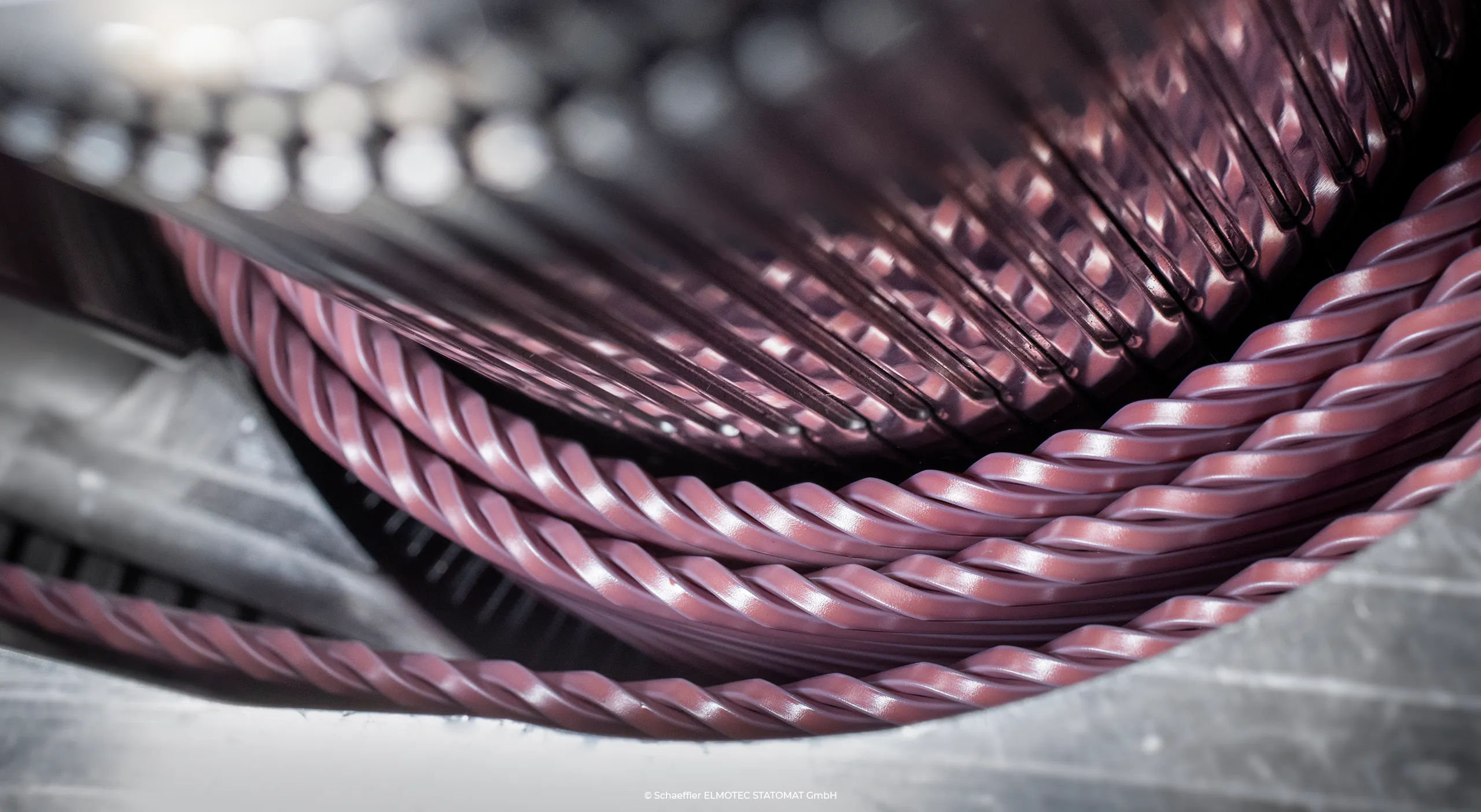

Wir haben SolarEdge e-Mobility bei der Herstellung des Stators für einen kompakten Elektromotor mit Hairpinwicklung unterstützt.

Das innovative Druckverfahren ermöglicht eine deutlich höhere Flexibilität für die 800V- und 400V-Ebene. Das 3D-Druckverfahren ermöglicht einen geringeren Werkzeugbedarf und hochkompakte Endwindungen. Darüber hinaus kann der optimierte Prozess auch andere Vorteile erzielen, wie z.B.:

- Hochkompakte Hairpin-Wickelköpfe

- Variables Stator-Design für jede Anwendung

Additive Drives bietet nicht nur das schnellste Prototyping auf dem Markt für Hochleistungs-Hairpinstatoren und Motoren, sondern auch maßgeschneiderte Lösungen für alle Branchen.